As the leading manufacturer of veneer peeling machines in China,today we will tell you how to set and operate the electric control box of our spindleless veneer peeling and cutting machine

Ⅰ Preparation Before Power-on

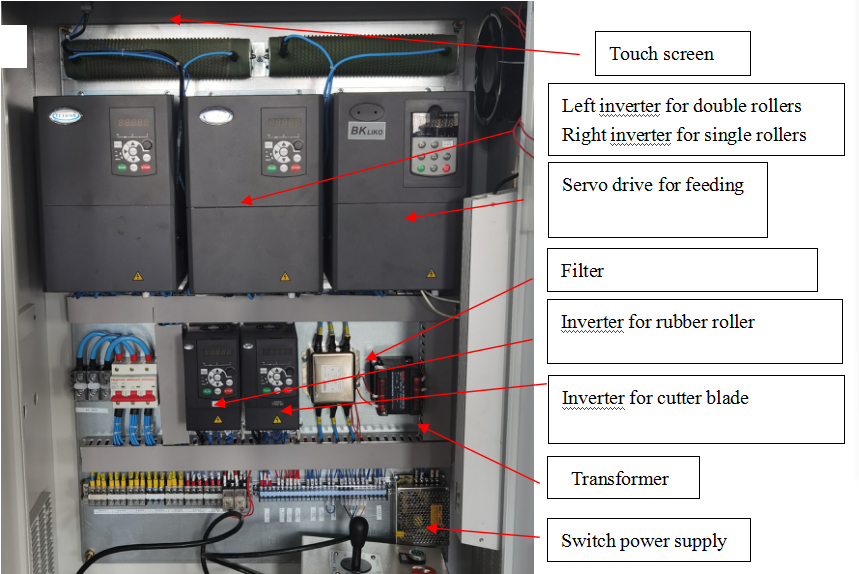

1.The name of the main parts of the electric box:

2.Wiring According to the Drawings

Make sure that the wiring of the input power supply, inverter and servo motor wires is correct, and the control wires are wired according to the wire numbers and markings.

Ⅱ First Time Power on & Commissioning

1.Power on and check whether or not there is alarm

Power on when the emergency stop switch is pressed,and observe whether there is any alarm in the inverter and servo drive.

If there are alarms,please refer to the alarm list in the Appendix,and troubleshoot.

2.Test whether the servo is running normally

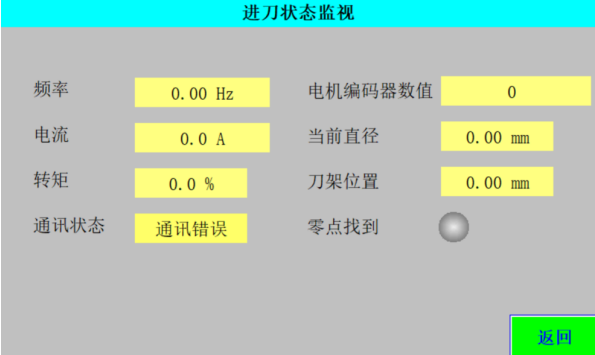

Release the emergency stop switch,press the fast forward or fast backward button,and

observe whether the output current in the touch screen is normal.

Status Monitor--->>Feed Status Monitor.

If the current exceeds 10A, please press the emergency stop, turn off the power switch,and swap the two terminals A1+ and A1- on the servo controller. Turn on the switch and repeat the above operation,and check the current

3.Check whether the feeding direction is correct

Operate the joystick to fast forward and fast backward. If the direction is not correct, please turn off the power switch, swap the servo motor wires U and V. Meanwhile,swap the A1+ and A1- terminals on the servo drive

4.Check the limit switch(NC)

Fast forward to the positive limit,and observe whether the knife table stops when it hits the positive limit

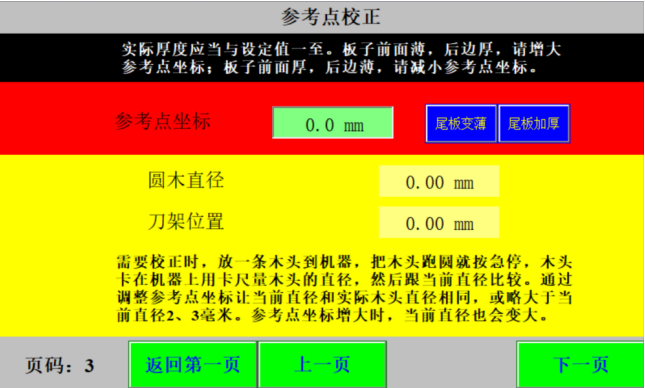

5.Find the zero point and input reference point coordinate

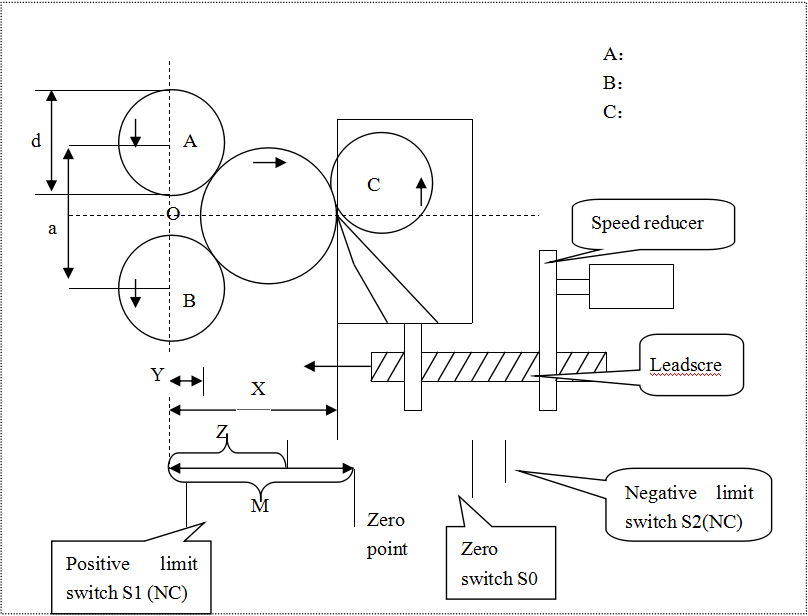

Operate the joystick to start,the blade carrier will move backward automatically to find the zero point.When the blade carrier touches the negative limit switch,it will move forward and will stop when it is 1mm away from the negative limit switch.Do not press any buttons at this time.Meanwhile,measure the distance from the tip of the blade to the center of the double roller (as X in the figure below) ,and input this distance into the “Reference Point Coordinate” on page 3 of the screen.

6.Check the rotating direction of the rollers

After find the zero point,press “Start”again to start the rollers,conveyor belt and rubber roller,and observe whether the rotation direction of the motor is correct.If incorrect,power offer and adjust the motor sequence.

Note:The rollers can only be started when the bold dot “Zero Point Found”on the homepage turns green.

7.Check the running direction and stop angle of the cutter blade

Press the start button again,it will start peeling automatically,and the cutter blade will start rotating automatically,pay attention to the rotation direction of the cutter blade.

Press the stop button,the peeling blade carrier will stop automatically advancing,the cutter blade will also stop rotating,and the angle at which the cutter blade stops should be forward and upward.If it is not correct,please adjust the position of the “Cutter zero point sensor” .

8.Set the correct mechanical parameter

Please contact the manufacturer of the spindleless veneer peeling machine,do not set it privately,do it as your own risk!

9.Perform idle test and observe whether the actions are correct

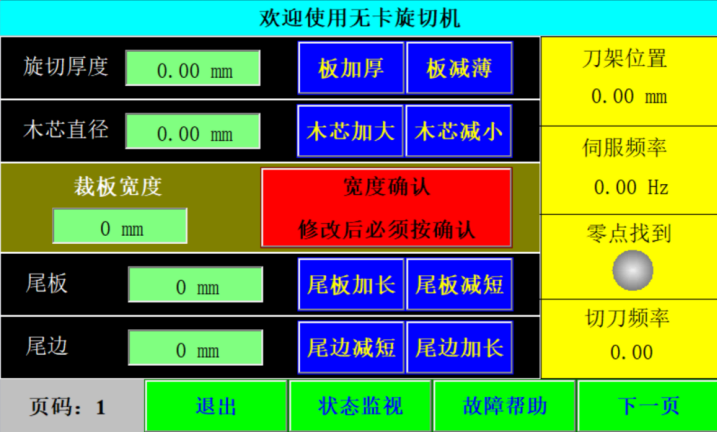

Set the diameter of the left wood core on the first page a bit larger, press Start to start automatic peeling, and observe whether the actions are normal.

Copyright © Hebei Qianhui Macihnery Co.,Ltd. All Rights Reserved | Sitemap |

Technical Support: