As the manufacturer of spindleless veneer peeling machine and

plywood hot press machines,today we will continue to tell you how to use our

4ft spindleless veneer peeling and cutting combined machine

Ⅲ Start Peeling

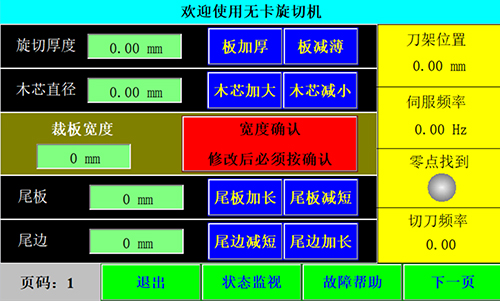

1.Set the working parameter you need

Set the working parameter you need on the first page.After setting the “Cutting Width”,

you must press the red button on the right to confirm.

“Last Veneer”is the compensation for the last piece of veneer,

the larger the setting,the longer the last piece of veneer will be .

“Last Edge”is the compensation for the last piece of edge,

the smaller the setting,the longer the last piece of edge will be.

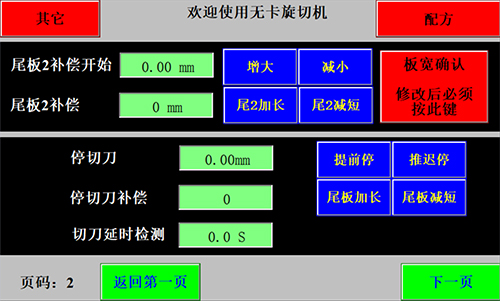

2.Special Compensation

2.1.Last Veneer 2 Compensation Function

You must press red button to confirm after modification.

2.2.Last Veneer Cut Twice

For some models of the peeling machine,the last piece of veneer needs to be cut twice,

which is suitable for this function.

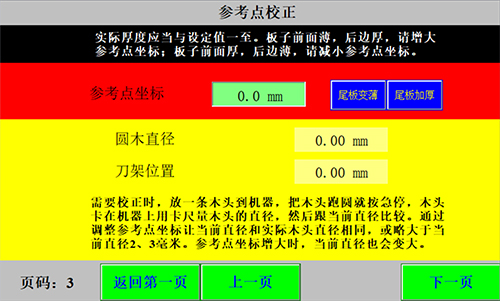

3.Reference Point Correction

Please read the instructions on the screen for the setting method

The actual thickness should be consistent with the set value.If the front veneer is thick

and the rear veneer is thin,increase the reference point coordinate(RPC);if the opposite,reduce the RPC

If need to correct,put a log into the machine and round it,then press emergency stop.

keep the log stuck in the machine and measure its actual dia with a caliper,

compare the dia with current dia.Adjust RPC to make the current dia same as the actual dia

or slightly larger than actual dia by 2-3mm.Current dia will increase when the RPC increases.

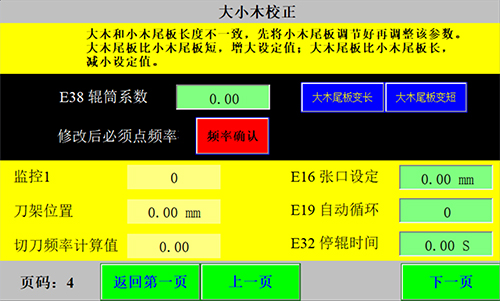

4.Big Diameter and Small Diameter Log Correction

Please read the instructions on the screen for the setting method

You must press red button to confirm after modification.

The length of last veneer for big dia and small dia logs are inconsistent,first adjust the length

of last veneer for small dia logs then adjust this parameter.

If the last veneer of big dia logs is shorter than that of small dia logs,increase the set value;

If the opposite,reduce the set value.

5.Roller Speed Setting

You must press red button to confirm after modification.

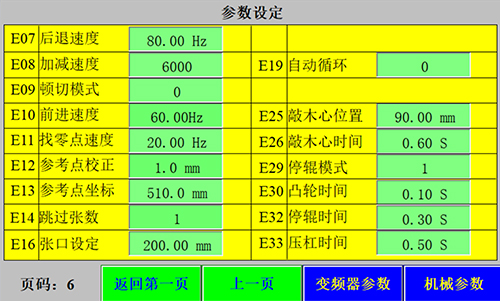

6.Parameter Setting

Do not set the parameter by yourself.If you need to change the parameter,please consult

the manufacturer of the wood veneer peeling lathe

Parameter Number | Parameter Name | Parameter Description | Range |

E07 | Backward Speed | Manual and automatic backward speed | 0~100 |

E08 | Acceleration Deceleration | Acceleration and deceleration settings | 5000-10000 |

E09 | Cutting Mode | 1:For cutting long veneer. | |

E10 | Forward Speed | Manual forward speed | 0~100 |

E11 | Speed of Finding Zero Point | The speed of finding zero point | 0~50 |

E12 | Reference Point Correction | Correct the reference point | |

E13 | Reference Point Coordinate | ||

E14 | Skip Number | How many sheets of veneer will be skipped without cutting at the beginning | |

E16 | Diameter setting | The max peeling diameter you need | |

E19 | Automatic Loop | 0:Stop after peeling is completed 1:Automatic feeding after peeling is completed | |

E25 | Knock Position | The position where the left log core will be knocked down | |

E26 | Knock Time | The time it takes to knock down the left log core(For machines with air cylinder knocking dwon system) | |

E29 | Roller Stop Mode | 0:Double Rollers do not stop; 1:Double Rollers stop | |

E30 | Cam Time | The minimum time the motor takes to knock down the left core(for machines with motor knocking down system) | |

E32 | Roller Stop Time | If set to 0,the last edge will not be cut | 0~0.6 |

E33 | Pressing Bar Time | The time the pressing bar is pressed down | 0~3 |

Copyright © Hebei Qianhui Macihnery Co.,Ltd. All Rights Reserved | Sitemap |

Technical Support: